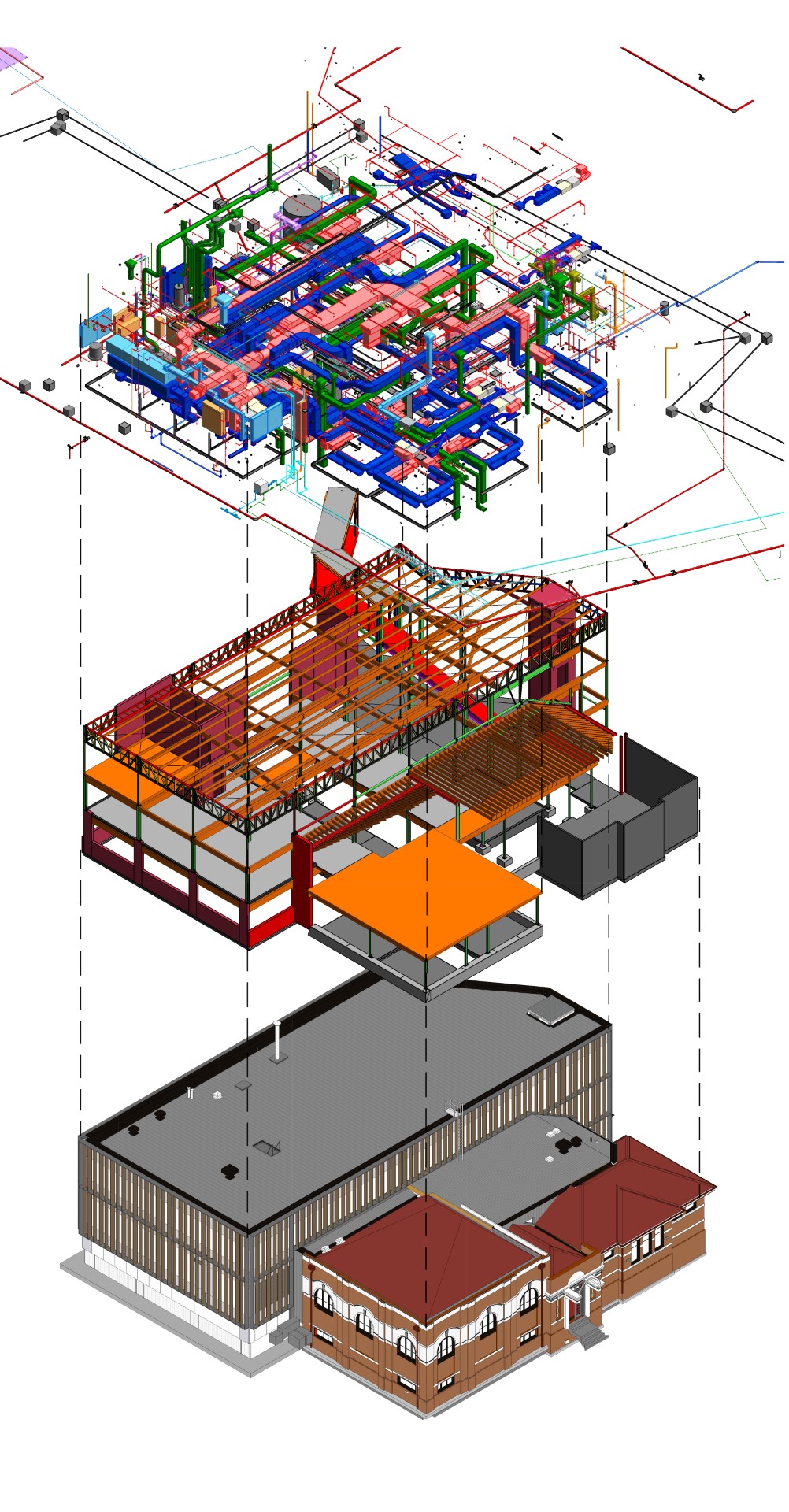

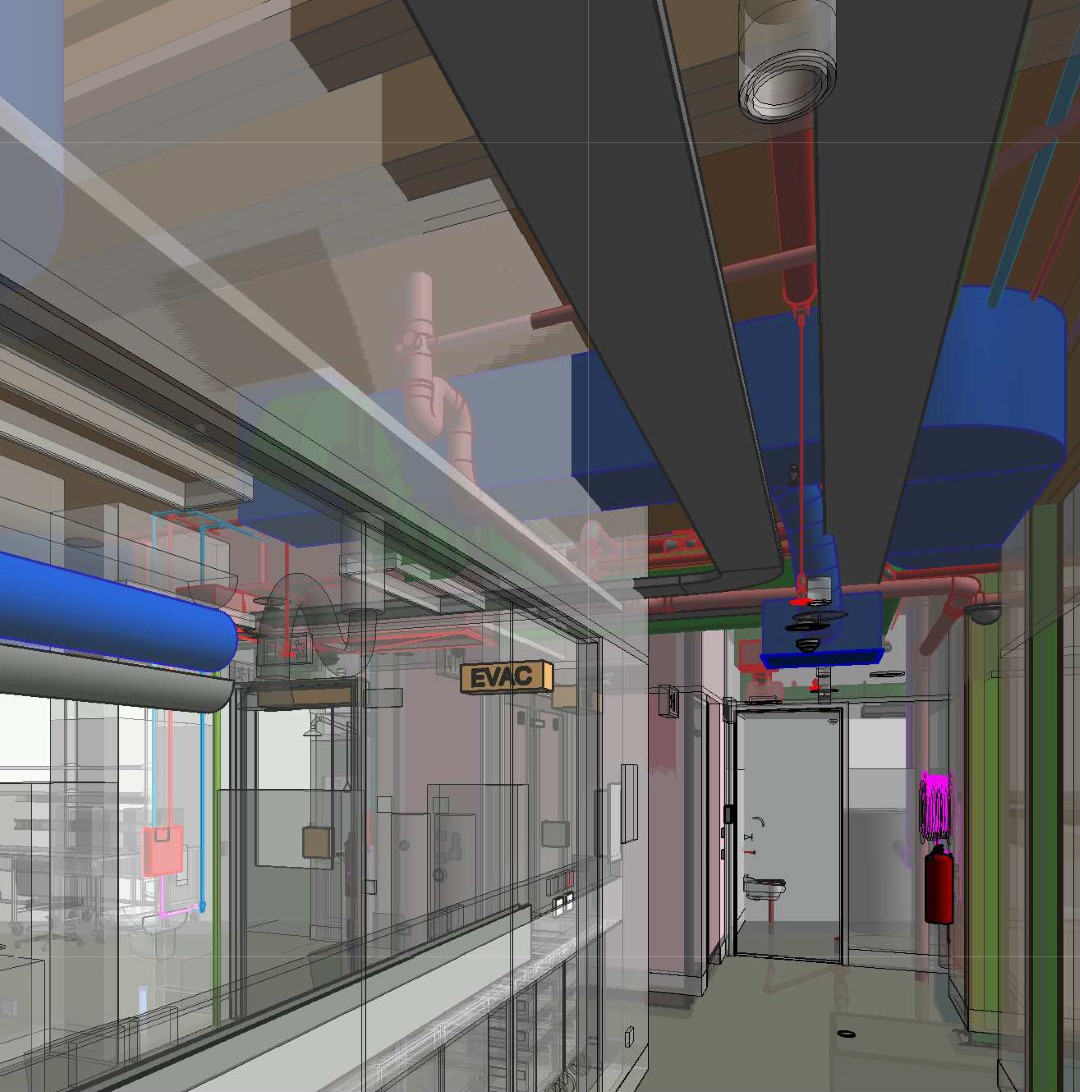

Figure 1: A diagram representing the layers of BIM modelling for Bio 21 Stage 2C.

Creating a digital model

Using a set of integrated software tools, we generated a sophisticated digital model of the site and project, which provided the framework for 3D coordination, allowing us to test design ideas and materials and functional requirements. This process was especially important as the project combined two compounding challenges:

- as a scientific research building, many building requirements were precise and left no margin for error

- the contemporary building would be located on a tight and restricted site and retain the historic frontage of the former Veterinary Research Institute Building, a dilapidated red brick building from the 1920s

The process of creating a model began by surveying the site with terrestrial 3D laser scanning and aerial drone photography, providing data in a considerably shorter timeframe than traditional surveying. Using computational software, the data could be stitched together forming a reference point cloud model for our team to recreate in Revit.

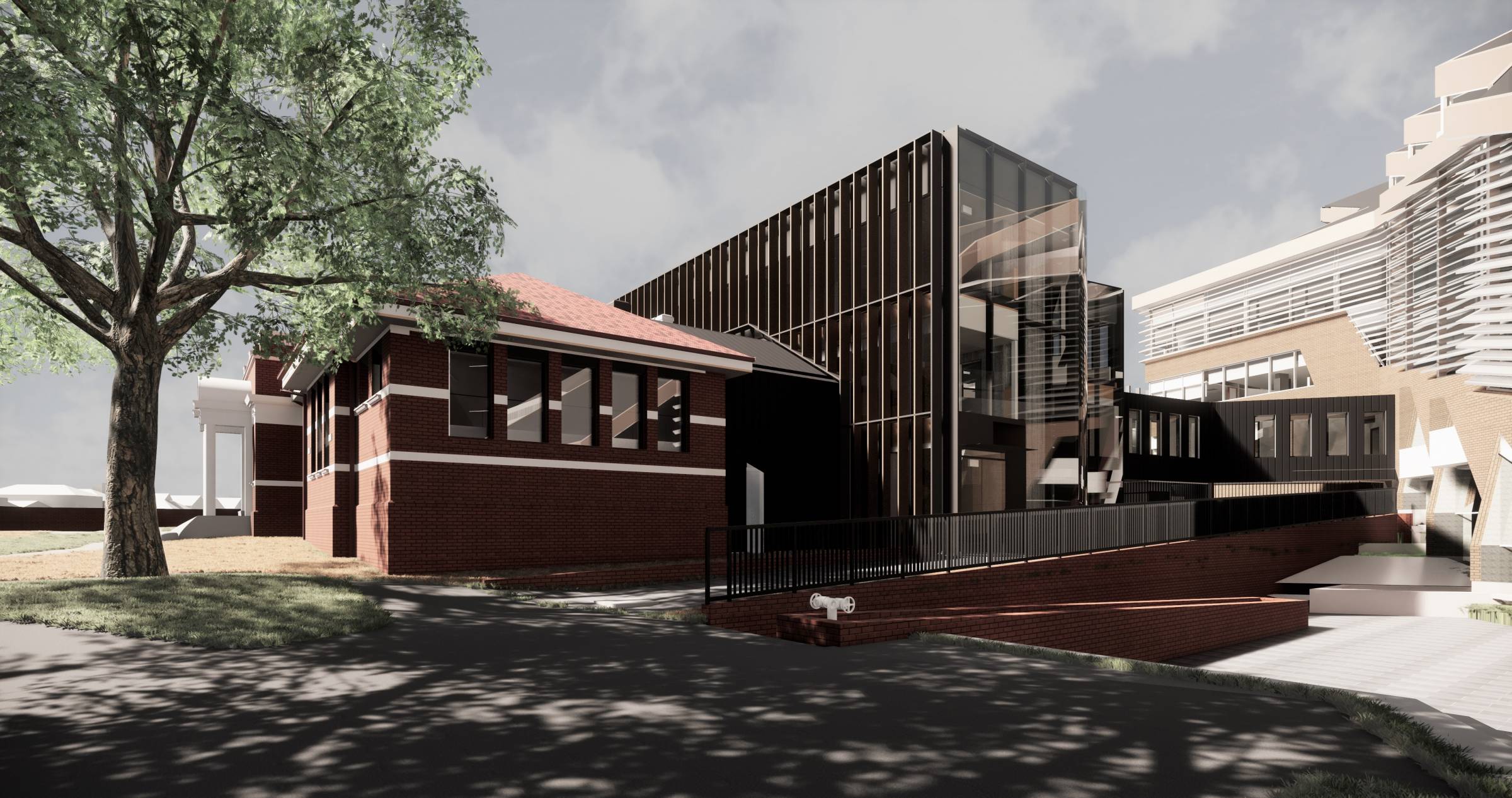

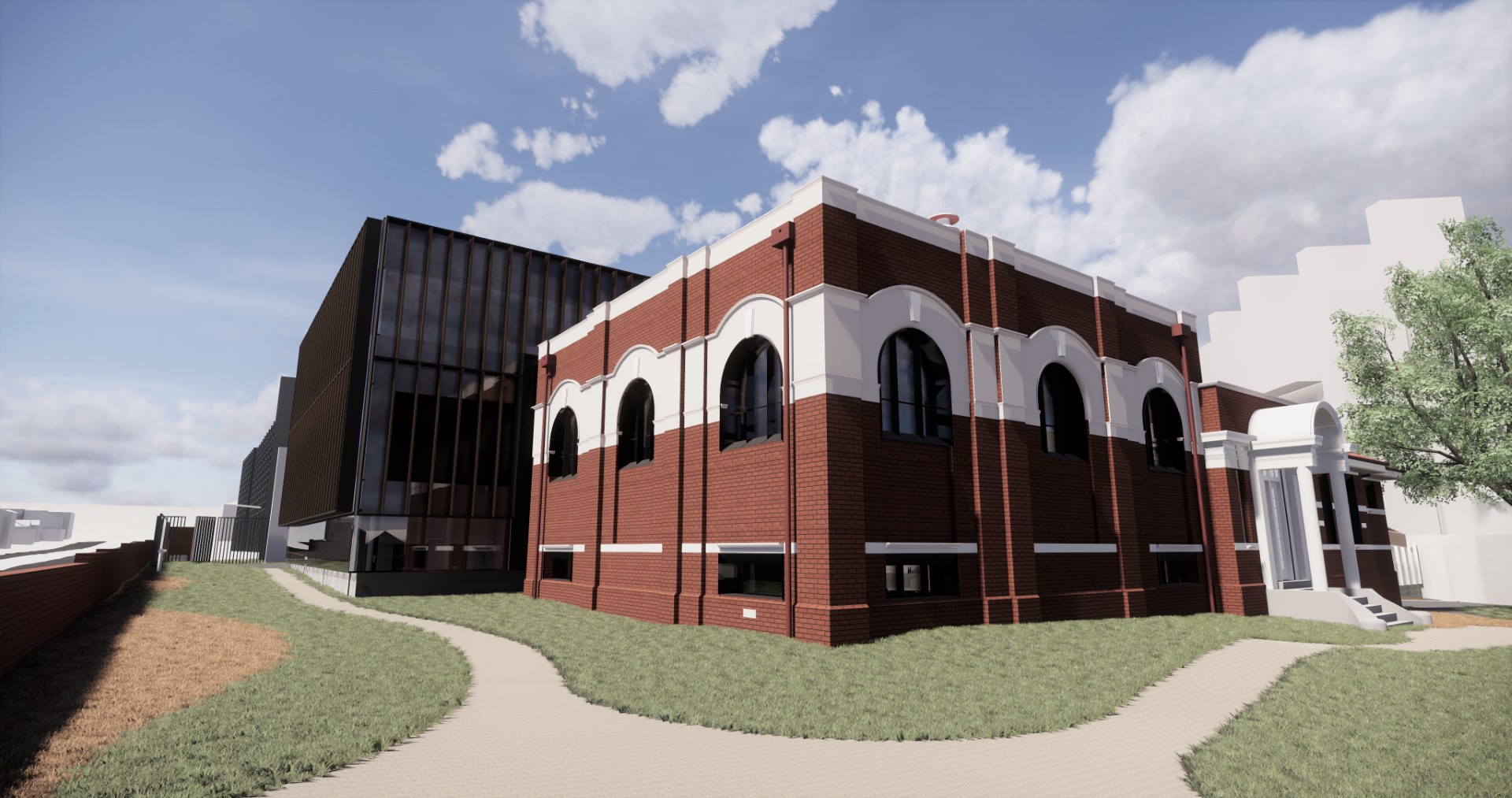

Figure 2 and 3: The building facade was scanned using terrestrial 3D lasers and aerial drone photography. This data formed a reference point cloud model that could be recreated in Revit.

Once we had a base model, we began modelling all research equipment and componentry, enabling us to test many layouts to achieve the most space-efficient solution. Importantly, our model also mapped interference zones and critical separations. For example, as a large moving metal object, the lift was a potential source of electromagnetic interference; our model created an exclusion sphere around the lift and electron microscopes were kept outside this zone.

As the design evolved and developed, more information was fed into the model, expanding its precision and capacity.

Figure 4: Views of the design were generated from the BIM model (top image) and the completed project was photographed (bottom image).

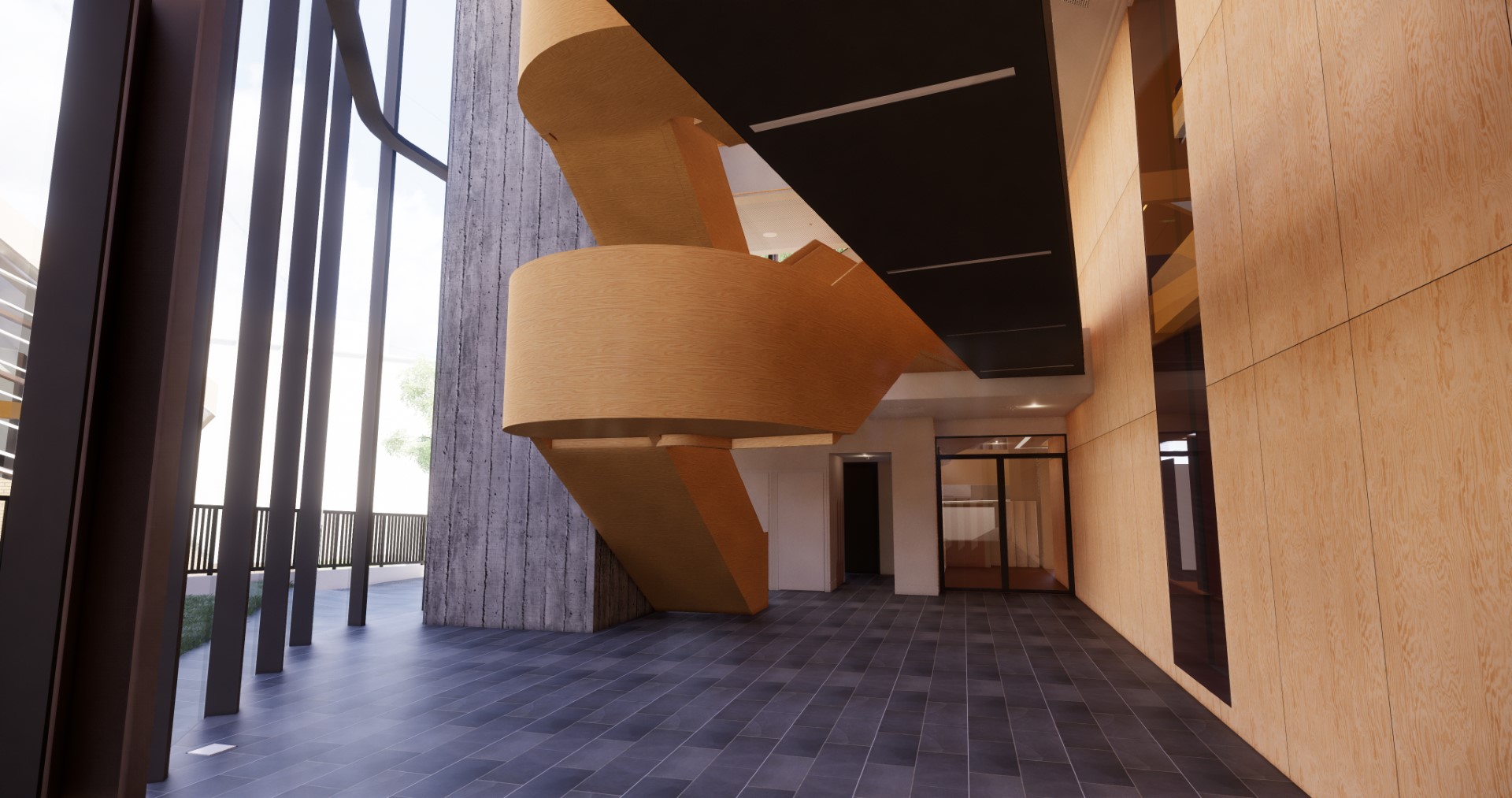

Communicating design

We used renders generated using Enscape to assist with explaining the materiality of the building to the client and stakeholders. The images we shared had an incredibly precise resolution of colours and finishes that gave the client complete understanding of what we were proposing, leading to a streamlined approval process.

Figure 5: The Electron Microscopy room was included in the stakeholder VR experience.

Virtual reality simulation

Even a decade ago, creating project specific virtual reality simulations was beyond the scope of most projects. Now it is increasingly part of our process, especially when we’re refining the design of technical projects for specialist staff.

The staff and researchers of Bio21 have a far more intricate understanding of the everyday complexities of their work. We generated a virtual reality simulation of research spaces within the new building that staff could explore using a virtual headset. Safety is paramount in research environment and the VR experience was a great operational check; for example, scientists could “walk” from the samples prep lab to the microscopy suites and understand the spatial sequence, the duration of the journey and the thresholds they had to pass through. The feedback that came out of these VR workshops guided several significant modifications, including reconfiguration of the layout of the electron microscopy labs, and tuning the position and size of glazed viewing portals.

Figure 6: Our BIM team issued models that formed the basis for LOD400 trade models.

3D coordination

We issued models that formed the basis LOD400 trade models that were used to coordinate the highly complex building services through construction. A new generation of timber construction using factory produced modules of cross-laminated timber was chosen for its non-conductive qualities (in terms of electromagnetic charge), cost and efficiency. This fabrication process enabled quick construction timeframes but left no room for error. We meticulously reviewed 3D trade models against our own 3D models throughout shop drawing and construction stages.

Model federation and clash detection was used to improve coordination of the complex building services found in the engineering models.

A precise road to a precise outcome

Living through the COVID-19 pandemic has shined a bright light on the importance of science and the buildings and spaces that facilitate research in the field. For scientists to work most efficiently and effectively they must have access to spaces that are seamlessly designed for the specific and highly technical nature of their work. BIM modelling and computational design processes increasingly underpin this, enabling architects to deliver buildings that consider functionality through every layer of design.