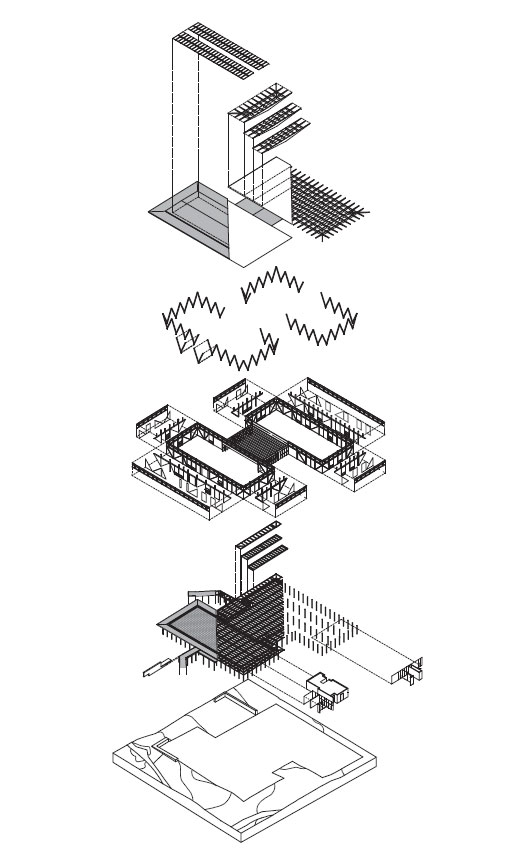

Multiple geometries for the external envelope and roof profile to the incubator were analysed and tested by our design team for their clarity of expression, buildability, structurally

innovative qualities and capacity to accommodate a diversity of internal workplace micro-environments and the regular churn that they will have to enable.

A modular prefabricated construction methodology was chosen to meet the swift 12-month design and construct program and the potential future dis-assembly, relocation and reassembly. With guidance provided by the expertise of ARUP Structure (Sydney) it was determined that the ceiling diaphragm would comprise of Cross Laminate Timber (CLT), large span Laminated Veneer Lumber (LVL) beams and Glulam V columns. This system proved ideal for achieving efficiencies in structural spanning, innovation in fabrication and installation, the potential for 100% re-use, and that it would introduce visual dynamism across a uniform structural system. The roof plane supports Building Integrated Photovoltaic (BIPV) technology in its sky-facing surface. The vertical envelope is composed of panels of plywood, CNC-cut to optimise material use from standard sheet sizes and arranged to generate a distinctive visual identity for the Macquarie University Incubator.

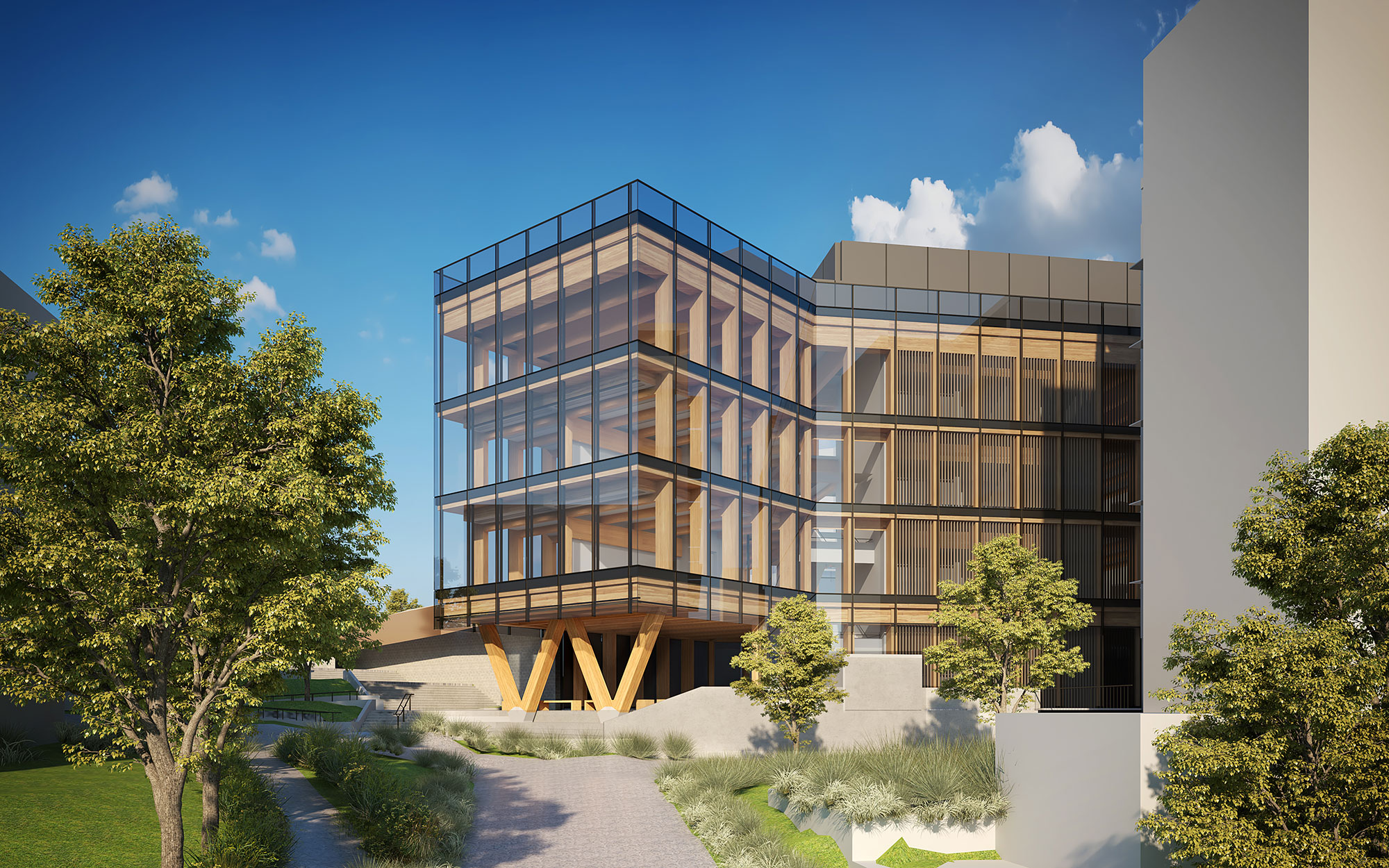

Macquarie University Clinical Education Building

The Macquarie University Clinical Education Building will foster a culture of transformative learning amongst academic and professional staff, promoting interprofessional enquiry-driven learning while combining clinical care, integrated teaching and research.

The MUCEB will establish an academic health precinct, promoting collaborative engagement between education, training, research and clinical practice.

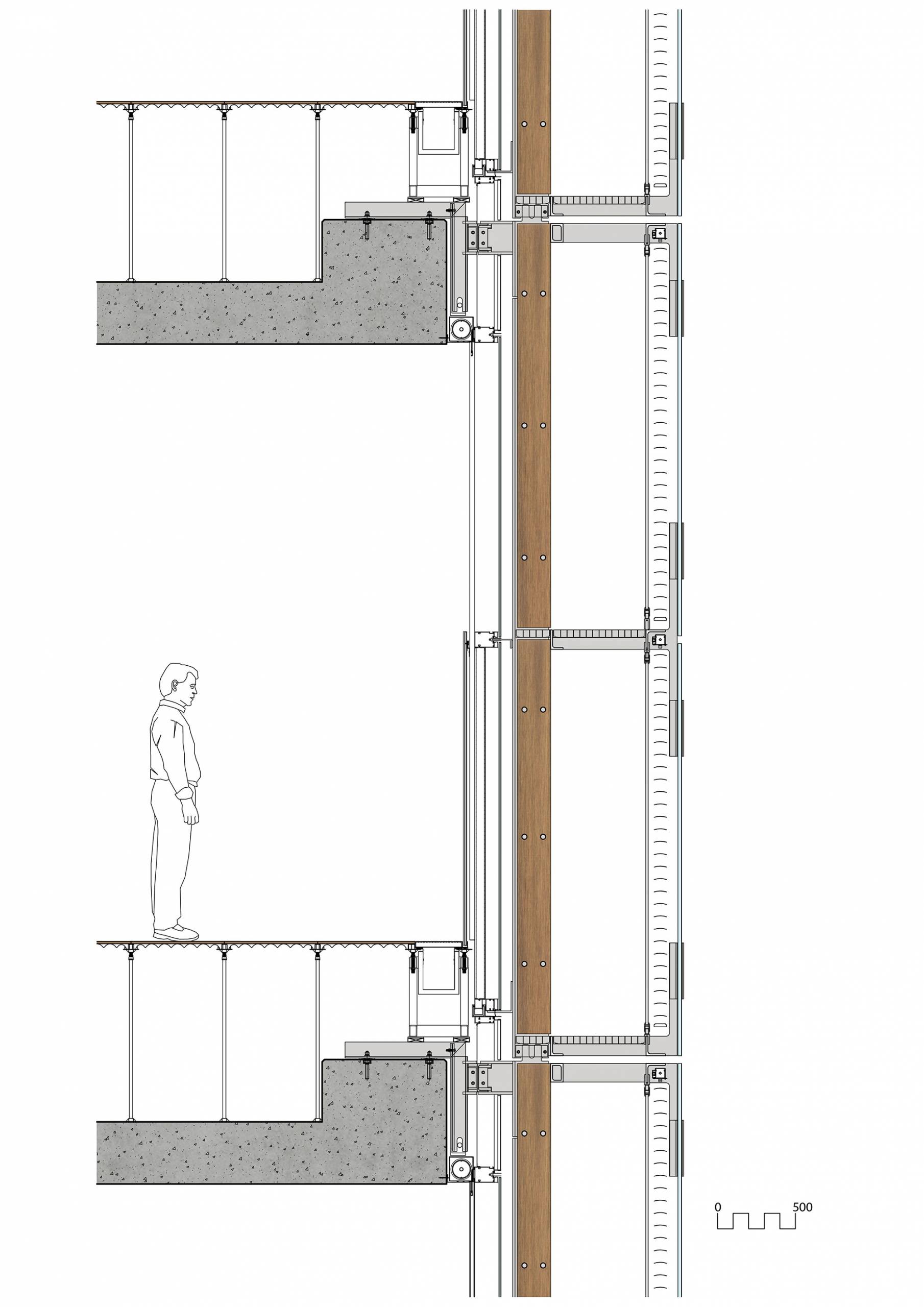

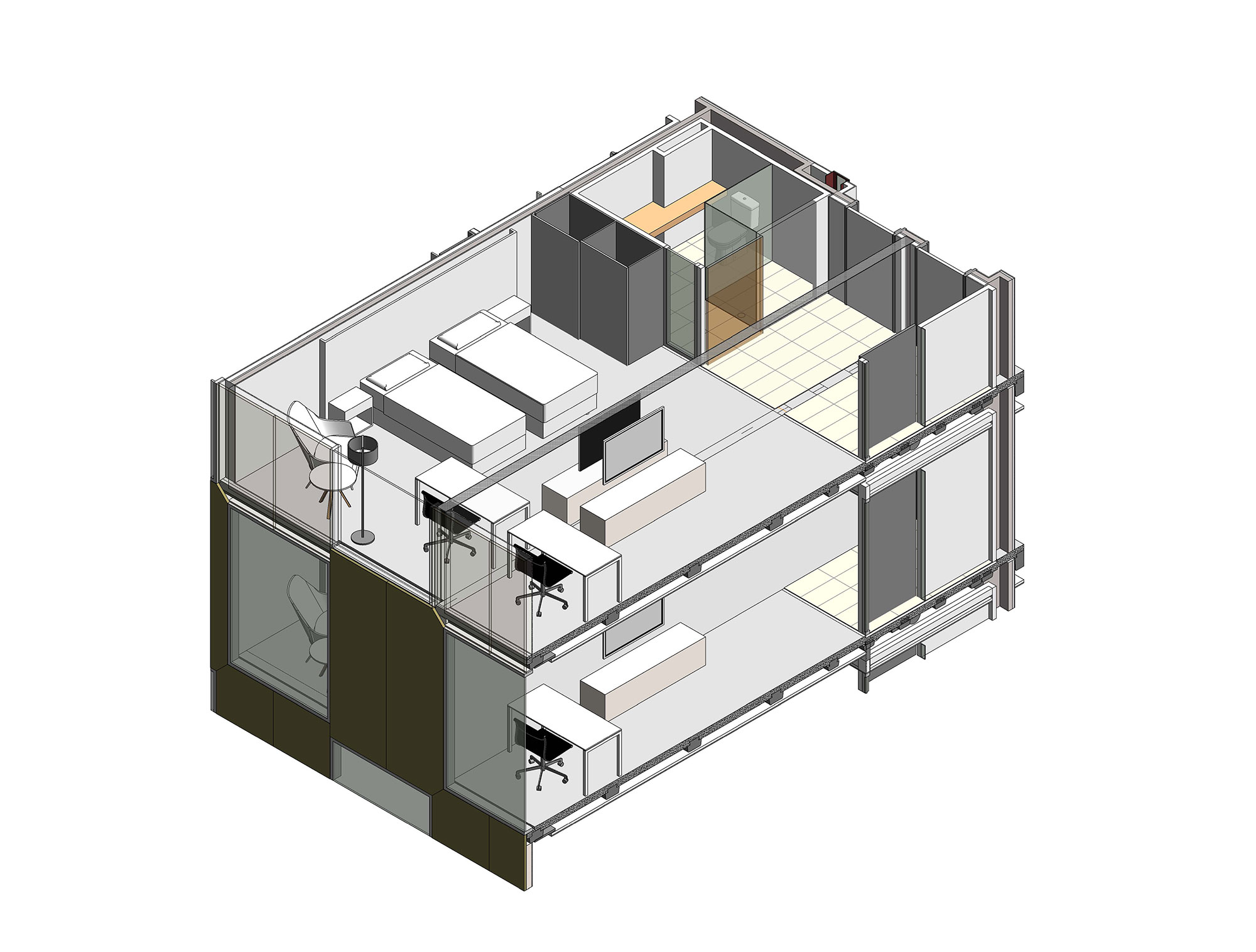

The building utilises cutting-edge digital prefabricated construction methods enabled by the multi-level timber engineered structure. This was highly important due to the site constraints, specifically being located next to an activate hospital. Prefabrication meant more up-front coordination and early detail resolution to enable overseas fabrication and longer procurement lead times.

Spruce Glued Laminated Timber (Glulam) has been used for columns and beams. Cross Laminated Timber (CLT) has been used on all floors from level one, and all core walls (including lift shafts). The only concrete used in the project is the ground floor slab. The external ‘W’ columns are Victorian Ash Glulam which has been locally sourced from Victoria.

Werribee Mercy Hospital Acute Expansion

This ambitious 4 level expansion on top of the recently completed Stage 1A works (Catherine McAuley Centre) provides 6 new operating theatres, Central Sterile Supply Department, 64 inpatient unit beds including 8 critical care beds and additional associated works including car parking for 140 cars.

There were many challenges during this build, the biggest being that the patients of the Werribee Mercy Hospital remained in their level 1 and 2 hospital rooms while the four levels were built above them. Right from the outset we were looking at modular, prefabricated solutions to ensure safe and speedy construction.

In a collaborative process, we worked with Multiplex and their sub-contractor FacadeX to develop a system that provided the structural, thermal and acoustic properties, all in one. It was very efficient and ticked all the boxes to allow us to meet the issues we were facing, such as Australian Standard fire-rating compliance.

The efficiency of this system contributed to the overall speed of the program, with the entire project completed in 18 months – two months ahead of schedule.

The six storey building has a strong presence on the Princes Highway and will signpost the Werribee Mercy Hospital as a cornerstone of support and care for the Wyndham community.

The panel system consists of an exterior rainscreen made from COLORBOND® steel which is fixed to steel sheeting that sandwiches a non-combustible insulation layer. The entire panel is fixed into a rectangular steel portal-frame that runs around its perimeter and the panels ‘clip’ together using a weatherproof mating system.

Queen Elizabeth II Courts of Law

The Queen Elizabeth II Courts of Law building is a radical departure from traditional court design. It exhibits a high degree of transparency and lightness – appropriate to both the expression of contemporary justice and to its subtropical locale.

The façade comprises a 5.4m high x 2.4m wide x 1.2m deep prefabricated double skin modular façade system. The modularisation of the façade permitted a complex façade solution to be achieved without scaffolding to align with the construction programme for the building. The façade system comprises a reinforced, extruded aluminium framed, unitised double glazed curtain wall panel with external steel framing supporting an outer skin of clamp fixed laminated glass with grated walkways and automated blinds within the cavity. Each unit weighed approximately 2500kg and was installed via crane and monorail. Individual module components were fabricated in China and transported to Australia for assembly in a plant on the outskirts of Brisbane. Panels were assembled flat and then lifted upright using a custom fabricated lifting frame.

Strategically patterned fritting distributed across the two layers of glass provides visual privacy where required, and it is scaled so that external views are maintained whilst views into the building are fragmented.

Parkroyal Parramatta Hotel Extension & Refurbishment

The extension and refurbishment to the existing Parramatta Parkroyal Hotel included an additional 90 guest rooms, new executive club lounge, additional meeting and function rooms, extended restaurant and other hotel amenities, and transformed the property into the premier business accommodation and conferencing facility in Western Sydney.

The project used the most modern, cost-effective construction methods; AFS Modular Construction fibre cement-lined wall carcases were easily placed in precise position by two workers, and then filled with concrete to provide the equivalent of an in-situ concrete shear wall, able to provide the necessary structural support, while eliminating the need for costly, time-consuming and wasteful formwork construction. Ultrafloor beam shells, combined with Bondek infills, provided a permanent formwork solution for floors which drastically reduced the need for back-propping.

Shallower Ultrafloor beams at closer spacings were used where floor setdowns were required, ensuring that prefabricated bathroom pods aligned perfectly with surrounding finishes without the need for steps or ramping. A concrete topping slab completed the system. Used in combination with the AFS system, the floor cycle was reduced to a minimum. The bathroom pods, with their off-site manufacture, produced the highest level of finish, and quality control. Construction times were reduced, and rework of damaged or poorly built elements was eliminated. Used in combination, these methods achieved optimised performance, higher quality, and shorter construction times when compared against traditional construction methodologies.

The extension and refurbishment to the existing Parramatta Parkroyal Hotel included an additional 90 guest rooms, new executive club lounge, additional meeting and function rooms, extended restaurant and other hotel amenities and transformed the property into the premier business accommodation and conferencing facility in Western Sydney.

University of Melbourne William Macmahon Ball Theatre

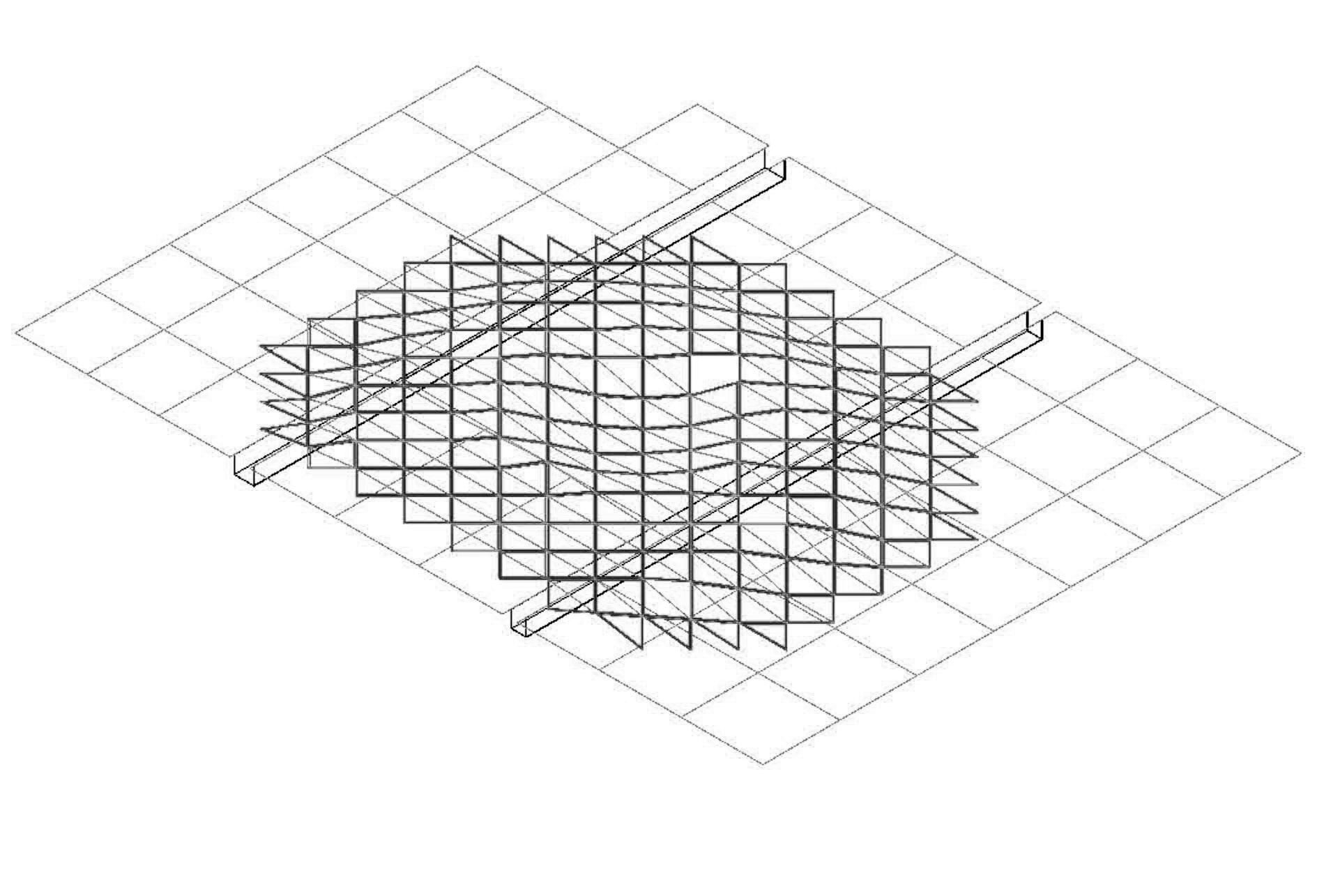

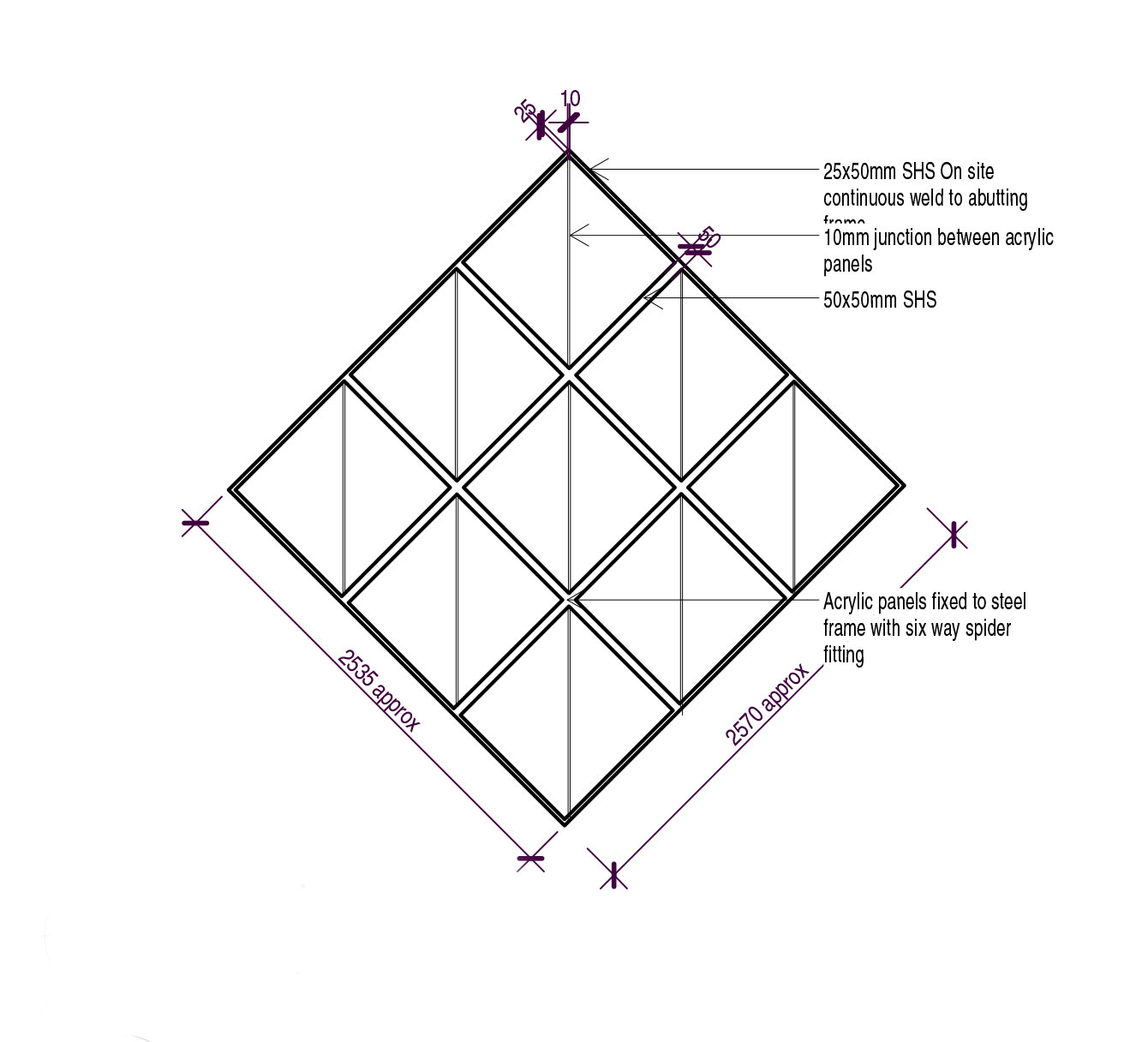

The ceiling of the William Macmahon Theatre at the University of Melbourne is defined by triangulated planes of translucent acrylic, suspended below stretched, acoustic fabric.

The undulating, glowing contoured ceiling form is a light fitting, a skylight and a sound dispenser – defining space, lighting the room and distributing sound evenly to all occupants, no matter where the speaker is positioned.

The ceiling geometry is both facetted and undulating. In a collaboration with programmers within the University of Melbourne’s Faculty of Architecture, our 3D model was optimised by using a plug-in to the program ‘Grasshopper’ which rationalised the number of unique geometries in the ceiling.

We ended up with 13 unique shapes which were then robotically cut by the fabricator and assembled on site. While revolutionary for its time in 2014, this kind of optimisation is now regularly used in Architectus projects.

The Forum ceiling of the William Macmahon Ball Theatre is defined by triangulated planes of translucent acrylic, suspended below stretched, acoustic fabric.